Choosing the right PCB manufacturer can make or break a project. With countless options available, understanding what to look for is crucial for ensuring quality, reliability, and cost-effectiveness. This article will guide readers through key factors to consider when selecting a manufacturer, helping them make informed decisions that align with their specific needs and goals.

Understanding PCB Manufacturing

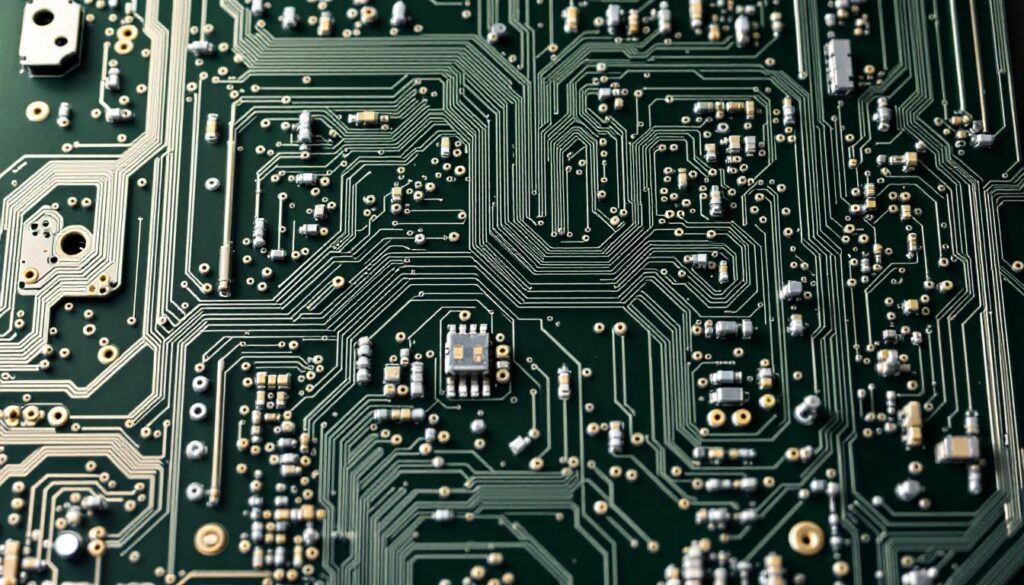

Understanding PCB manufacturing involves recognizing its critical components and processes. Printed Circuit Boards (PCBs) serve as the backbone of electronic devices. Their function is to mechanically support and electrically connect electronic components through conductive pathways.

Key Processes in PCB Manufacturing

- Design: The design phase incorporates software tools like Altium Designer and Eagle PCB. Designers create schematics and layout, optimizing for manufacturability.

- Material Selection: Selecting materials is vital. Common substrates include FR-4, a glass-reinforced epoxy laminate. Understanding material properties impacts thermal and electrical performance.

- Fabrication: Fabrication transforms designs into physical boards. This process involves several steps such as etching, drilling, and plating, which build the layers of the PCB to form connections.

- Assembly: PCB assembly involves placing and soldering components onto the fabricated boards. Methods like surface mount technology (SMT) and through-hole technology (THT) determine how components attach to the board.

- Testing: Comprehensive testing identifies defects. Methods such as Automated Optical Inspection (AOI) and electrical testing verify functionality and integrity.

Importance of Quality Control

Quality control ensures PCBs meet industry standards like IPC-A-600. Rigorous testing at each manufacturing stage helps prevent defects, which can lead to failures in end products. Manufacturers often adhere to premium quality certifications, such as ISO 9001, ensuring consistent delivery of reliable PCBs.

Factors Influencing PCB Manufacturing Choices

- Volume Requirements: High-volume production may require advanced manufacturing techniques to reduce costs. Conversely, small runs can use different strategies that accommodate lower quantities.

- Lead Time: Understanding lead times is critical. Shorter lead times may require prioritizing certain manufacturers, especially for urgent projects.

- Cost vs. Quality: Balancing cost and quality is essential. While lower costs might attract choices, they could indicate potential compromises in quality or reliability.

Understanding PCB manufacturing equips individuals to make informed decisions when selecting a manufacturer. Each step of the process, from design to quality control, plays a significant role in delivering a functional and reliable product.

Key Factors to Consider

Selecting a Printed Circuit Board Assembly Manufacturer like OurPCB involves careful consideration of several key factors that affect quality, reliability, and cost.

Quality of Materials

Choosing high-quality materials ensures the PCB meets performance standards. Manufacturers often use materials such as FR-4 for general applications and Rogers for high-frequency designs. Certifications from ISO and UL can indicate adherence to quality standards. Examine the manufacturer’s sourcing practices to confirm the use of reliable suppliers.

Manufacturing Processes

Understanding the manufacturing processes provides insight into the production capabilities of a PCB manufacturer. Key processes include etching, drilling, and layering. A manufacturer’s ability to implement advanced techniques, such as automated optical inspection (AOI) and visual testing, enhances defect detection and quality assurance. Investigating their process certifications can provide further assurance.

Design Capabilities

The design capabilities of a manufacturer should align with project requirements. Look for a manufacturer that supports multiple design formats and offers services such as layout optimization and design rule checking. Assess their experience with specific technologies, including surface mount technology (SMT) and through-hole assembly. High-level design support can lead to reduced production errors and improved time-to-market.

Assessing Manufacturer Experience

Evaluating the experience of a PCB manufacturer is crucial for ensuring project success. An experienced manufacturer typically has established processes and a track record of producing reliable products.

Industry Reputation

Industry reputation plays a significant role in assessing a PCB manufacturer’s experience. Manufacturers known for high-quality standards and technical expertise often receive recognition from industry organizations. A strong reputation indicates reliability in delivering products that meet specifications and performance requirements. Research industry awards, certifications, and associations to gauge a manufacturer’s standing in the market. Additionally, consider whether the manufacturer is well-regarded among its peers and competitors, which often reflects their experience and capability.

Customer Reviews and Case Studies

Customer reviews and case studies provide valuable insights into a PCB manufacturer’s experience. Companies that have successfully worked with a particular manufacturer often detail their experiences in reviews. Look for testimonials that mention product quality, customer service, and timely delivery. Case studies showcase specific projects, highlighting the manufacturer’s ability to meet unique challenges. Analyzing these feedback sources helps reveal the manufacturer’s strengths and weaknesses, aiding informed decision-making when selecting a partner for PCB manufacturing.

Cost Considerations

Cost remains a vital factor when selecting a PCB manufacturer. Understanding the financial implications can guide decisions effectively.

Pricing Models

Manufacturers often employ different pricing models, impacting overall cost. He or she should consider:

- Flat Rate Pricing: Manufacturers offer a set price per board regardless of order size. This model suits smaller projects or low-volume production.

- Volume-Based Pricing: Costs decrease per unit as order quantity increases. This approach benefits large-scale projects.

- Time and Materials Pricing: This model covers costs based on actual time spent on production and materials used. This option is less predictable but can be useful for custom jobs.

Hidden Costs to Watch For

Hidden costs can significantly affect the total expenditure. Potential hidden costs include:

- Setup Fees: Some manufacturers charge for initial setup, especially for custom designs. These fees add to the overall price if not accounted for early.

- Shipping Costs: Manufacturers may offer low production prices but charge high shipping. Always confirm shipping details to avoid surprises.

- Design Modifications: Changes to the PCB design after production starts can incur additional charges. Redesign fees can quickly add up.

- Prototype Costs: Testing prototypes often involves extra charges, particularly if multiple iterations are needed. Ensure to factor these costs into the overall budget.

Awareness of these cost considerations leads to more informed decision-making when choosing a PCB manufacturer.

Communication and Support

Effective communication and support are crucial when selecting a PCB manufacturer. Clear channels of communication facilitate project updates and timely responses to inquiries.

Response Times

Response times reflect a manufacturer’s commitment to customer service. An ideal manufacturer ensures replies are prompt, typically within 24 hours. Quick responses to questions about quotes, specifications, or support requests help maintain project momentum. Delays in communication can hinder progress and lead to costly setbacks, so assessing response times during initial interactions is essential.

Technical Support Availability

Technical support availability adds another layer of assurance when choosing a PCB manufacturer. Manufacturers should offer accessible technical support through multiple channels, such as phone, email, and live chat. Support should cover design consultations, troubleshooting issues, and guidance on manufacturing processes. Consistent access to knowledgeable experts can significantly improve the overall manufacturing experience and reduce potential errors during production.

Conclusion

Choosing the right PCB manufacturer is a crucial step in ensuring the success of any electronic project. By considering factors like material quality design capabilities and manufacturing processes readers can make informed choices that align with their specific needs.

It’s essential to evaluate a manufacturer’s experience and reputation as these elements often reflect reliability and expertise. Additionally understanding cost structures and maintaining effective communication can streamline the manufacturing process and improve overall project outcomes.

With the right approach selecting a PCB manufacturer becomes a strategic decision that can lead to improved product quality and efficiency.

Frequently Asked Questions

What is the importance of selecting the right PCB manufacturer?

Choosing the right PCB manufacturer is crucial as it directly impacts the quality, reliability, and cost-effectiveness of your project. A well-selected manufacturer can ensure that your PCBs meet industry standards and perform effectively, ultimately influencing the success of your electronic products.

What key factors should I consider when selecting a PCB manufacturer?

Important factors include the quality of materials, manufacturing processes, design capabilities, experience, industry reputation, and customer reviews. Assessing these elements will help you choose a manufacturer that aligns with your project’s specific needs and goals.

How does the quality of materials affect PCB performance?

High-quality materials are essential for optimal PCB performance. They ensure reliable connectivity and durability, helping your electronic devices function properly while meeting industry standards. Selecting a manufacturer that prioritizes material quality is therefore important.

What manufacturing processes are critical in PCB production?

Key processes include design using specialized software, material selection, fabrication methods like etching and drilling, component assembly, and rigorous testing. Understanding these processes helps ensure the eventual quality of the printed circuit boards.

How can I evaluate a PCB manufacturer’s experience?

You can gauge a manufacturer’s experience by looking at their history in the industry, project portfolio, and any certifications or awards they have received. Established manufacturers often have proven processes and a track record of reliability.

Why is industry reputation important when selecting a PCB manufacturer?

A strong industry reputation indicates reliability and expertise. Look for recognition from industry organizations and positive reviews from peers, which can provide valuable insights into a manufacturer’s capabilities and quality standards.

How do customer reviews help in choosing a PCB manufacturer?

Customer reviews and case studies offer real-world insights into a manufacturer’s performance. They highlight strengths and weaknesses that can inform your decision-making process, ensuring you select a partner suited to your specific needs.

What are the common cost considerations when choosing a PCB manufacturer?

Understanding cost considerations involves examining pricing models, identifying potential hidden costs (e.g., setup fees, design changes), and factoring in shipping rates. This knowledge aids in budgeting and ensuring the overall expenditure meets your financial constraints.

Why is effective communication important with a PCB manufacturer?

Effective communication ensures clear project updates and timely responses to inquiries, which can significantly enhance the manufacturing experience. Manufacturers who prioritize communication help reduce errors and ensure smooth collaboration during production.

What type of technical support should I expect from a PCB manufacturer?

A good PCB manufacturer should offer various channels for technical support, such as phone, email, and live chat. Responsive support, ideally within 24 hours, can significantly enhance your experience and resolve potential issues promptly.